1. Increased Protection for Your Boat

The primary function of a boat lift is to protect your boat from the wear and tear of being in the water. Accessories like bunk guides, bow stops, and guideposts can further enhance this protection. Bunk guides ensure your boat is positioned correctly on the lift, reducing the risk of hull damage. Bow stops prevent over-travel when docking your boat, and guideposts make it easier to position your boat, especially in windy or choppy conditions.

2. Ease of Use and Convenience

With the right accessories, using your boat lift becomes much easier and more convenient. Remote control systems allow you to operate your lift from a distance, which is especially helpful when you’re alone. Solar panels can be added to power your lift, eliminating the need for electrical wiring and reducing energy costs. Additionally, walkways and steps can be installed alongside your lift for easy and safe access to your boat.

3. Enhanced Safety Features

Safety should always be a priority when it comes to boating. Accessories like safety lights and alarms add an extra layer of security. Lights can be particularly useful for nighttime operations, ensuring you can see your surroundings. Alarms can alert you to any malfunction or unauthorized use of your boat lift, giving you peace of mind.4. Customization and Personalization

Every boat and boat owner is unique, and the ability to customize your boat lift with various accessories allows you to tailor it to your specific needs and preferences. Whether it’s adding a personal touch with custom colors or choosing accessories that cater to the size and type of your boat, personalization ensures that your boat lift meets all your requirements.5. Increased Durability and Longevity

Quality accessories can significantly extend the life of your boat lift. For example, using a canopy cover can protect both your boat and the lift from harsh weather conditions, UV rays, and debris. This not only keeps your boat looking new but also reduces the wear and tear on your lift, saving you money on maintenance and replacements in the long run

6. Improved Aesthetics

A boat lift doesn’t have to be purely functional; it can also enhance the visual appeal of your waterfront property. Many accessories are designed with aesthetics in mind, offering a range of styles and finishes that can complement your boat and the surrounding area. A well-chosen set of accessories can make your boat lift look more sophisticated and integrated into your waterfront space.7. Value Addition to Your Property

Investing in high-quality boat lift accessories can also add value to your property. A fully equipped and well-maintained boat lift is an attractive feature for potential buyers who are boating enthusiasts. It demonstrates a commitment to protecting and maintaining valuable assets, which can be a strong selling point.8. Environmental Benefits

Some boat lift accessories, like solar panels, not only provide operational efficiency but also offer environmental benefits. By harnessing solar power, you reduce reliance on non-renewable energy sources and minimize your carbon footprint, contributing to environmental conservation.9. Adaptability to Changing Needs

As your boating lifestyle changes, so can your boat lift. Accessories allow you to adapt your lift to accommodate different boats or new boating activities. This flexibility ensures that your investment continues to serve you well over the years, regardless of how your boating needs evolve. Check all of our boat lift accessories.10. Peace of Mind

Lastly, knowing that your boat is securely stored and protected gives you peace of mind. This is invaluable, especially when you are away from your waterfront property. The right set of accessories can ensure that your boat is safe, secure, and ready to use whenever you need it.

IQ Boat Lifts Recommended Accessories

Accessories that Make Boarding Your Boat Easier

- Elevator Boarding Platforms: Because elevator lifts ride on angled tracks, there is often a large gap between the dock and your boat. The “elevator boarding platform” fills in that gap, so you don’t have to leap so far.

- Hinged Platforms: Even with regular lifts, some people want a small platform that folds down to get closer to their boat, that they will fold up to get it out of the way when they are docking the boat.

- Top Beam Covers: Top beam covers are non-slip metal decking that attach to the top of the top beam. This allows you to safely walk on the top beams.

- Walkboard Steps: Steps can attach to the dock or walk boards and make it easier to board boats that are very high up.

Accessories that Provide Better Access to the Boat

- Walkboards: Adding a walkboard will provide a stable platform on the lift cradles to walk along.

- Cross Over Walkboards: These provide a rigid rectangle of boards attached to the lift cradles, providing access to all sides of the boat.

- Stern Platform: These provide a platform at the stern of the boat, making boat maintenance much easier.

Accessories to Bunk Specific Boats

- Dual PWC: Easily add bunking for two PWCs along with a walk board between, making getting on and off your personal watercraft much easier and safer.

- Stepped Bunks: Add this bunking that better fits boats with stepped hulls.

- Sailboat Bunking: This style of bunking is designed to accommodate the keels of sailboats.

- Freeman Bunks: Custom bunks can be designed to accommodate any hull. These bunks were designed to support Freeman-powered catamarans.

Boat Lift Accessories to Change the Look of the Dock

- Floating Dock & Gangway: Floating docks rise with the tides and our hinged gangways adjust to accommodate the changing tide levels.

- Decklifts: Use these when you deck over the boat lift cradles. Decklifts are a stable platform that provides 360-degree access to the boat, and you can choose your decking to match the dock.

- Low Profile: Add this as an accessory to your boat lift if you want to hide the boat lift top beams under the dock. Can also allow for the decked platform to be flush with the dock, giving you a seamless aesthetic.

In Conclusion

Adding accessories to your boat lift is a wise investment that goes beyond mere aesthetics. It enhances the functionality, safety, and longevity of your boat lift while providing convenience and peace of mind. Whether you are a seasoned boater or new to the world of boating, investing in the right boat lift accessories can significantly improve your boating experience. If you need help choosing the best boat accessories for your requirements, don’t hesitate to contact us.Frequently Asked Questions (FAQs) about Enhancing Your Boat Lift with Accessories:

Adding accessories to your boat lift can enhance its functionality, longevity, convenience, and safety. Accessories also contribute to protecting your boat and property while improving your overall boating experience.

Boat lift accessories include bunk guides, bow stops, guideposts, remote control systems, solar panels, safety lights, alarms, walkways, steps, canopy covers, and more. These accessories serve various purposes, such as boat protection, ease of use, safety enhancement, customization, and aesthetics.

Accessories like bunk guides ensure proper positioning of the boat on the lift, reducing the risk of hull damage. Bow stops prevent over-travel during docking, while guideposts assist in boat positioning, especially in challenging conditions like wind or waves.

Yes, many accessories are designed to make using your boat lift easier and more convenient. Remote control systems allow for distance operation, while solar panels eliminate the need for electrical wiring. Additionally, walkways and steps provide safe access to your boat.

Accessories such as safety lights and alarms add an extra layer of security to your boat lift setup. Lights improve visibility during nighttime operations, while alarms notify you of any malfunctions or unauthorized use, ensuring peace of mind.

Yes, boat lift accessories allow for customization and personalization based on your specific needs and preferences. You can choose custom colors, select accessories tailored to your boat size and type, and add features that complement your waterfront property.

Yes, high-quality accessories can extend the life of your boat lift by protecting it from harsh weather conditions, UV rays, and debris. Features like canopy covers minimize wear and tear, reducing maintenance costs in the long run.

Yes, a fully equipped and well-maintained boat lift with accessories adds value to your waterfront property. It demonstrates a commitment to protecting and maintaining valuable assets, making it attractive to potential buyers.

Some accessories, like solar panels, harness renewable energy sources, reducing reliance on non-renewable energy and minimizing carbon footprint. This promotes environmental sustainability and conservation efforts.

Yes, boat lift accessories offer flexibility, allowing you to adapt your lift to accommodate different boats or new boating activities as your lifestyle changes. This ensures that your investment continues to serve you effectively over the years.

However, it is incredibly important to be careful when choosing the fabric used for your boat lift slings. The best hoist slings are made from polyester – as opposed to nylon – due to the material’s low stretch value. A polyester boat sling more effectively maintains its working load limit when wet.

Another consideration when purchasing boat lift slings for sale would be to consider the thickness of the manufacturing material. For small personal watercraft like kayaks or jet skis, a 2-ply sling is likely sufficient. For larger vessels, 4-ply thickness offers heavy duty use and greater durability.

However, it is incredibly important to be careful when choosing the fabric used for your boat lift slings. The best hoist slings are made from polyester – as opposed to nylon – due to the material’s low stretch value. A polyester boat sling more effectively maintains its working load limit when wet.

Another consideration when purchasing boat lift slings for sale would be to consider the thickness of the manufacturing material. For small personal watercraft like kayaks or jet skis, a 2-ply sling is likely sufficient. For larger vessels, 4-ply thickness offers heavy duty use and greater durability.

Another advantage is the way that cradles can be customized to suit almost any setting – not just shallow water. With a few easy modifications, cradle lifts will accommodate watercraft of all sizes, shapes and materials.

Another advantage is the way that cradles can be customized to suit almost any setting – not just shallow water. With a few easy modifications, cradle lifts will accommodate watercraft of all sizes, shapes and materials.

Our

Our

One problem in marine construction has been the longevity of treated timber piles. Treated timber piles are subject to damage from hard driving, corrosion, fungal decay and biological organisms. Saltwater can accelerate the deterioration of timber. Over time, UV rays will dry out timber, creating cracks for salt and moisture to wick through. Once dried, salt crystals form in the timber cells and push the wood fibers apart.

One problem in marine construction has been the longevity of treated timber piles. Treated timber piles are subject to damage from hard driving, corrosion, fungal decay and biological organisms. Saltwater can accelerate the deterioration of timber. Over time, UV rays will dry out timber, creating cracks for salt and moisture to wick through. Once dried, salt crystals form in the timber cells and push the wood fibers apart. Fiber-reinforced polymer (FRP) composite pilings consist of a corrosion-resistant polymer, reinforced with carbon fibers. A long-lasting and dependable alternative to traditional materials, FRP composite pilings have exceptional strength and durability. They are well-suited for use in marine environments because they are unreactive to moisture and chemical corrosion. Furthermore, the Department of Environmental Protection has designated FRP as an environmentally safe, non-polluting material due to its chemical inertness. No more worries about the chemicals in your pilings leaching into the water!

Fiber-reinforced polymer (FRP) composite pilings consist of a corrosion-resistant polymer, reinforced with carbon fibers. A long-lasting and dependable alternative to traditional materials, FRP composite pilings have exceptional strength and durability. They are well-suited for use in marine environments because they are unreactive to moisture and chemical corrosion. Furthermore, the Department of Environmental Protection has designated FRP as an environmentally safe, non-polluting material due to its chemical inertness. No more worries about the chemicals in your pilings leaching into the water!

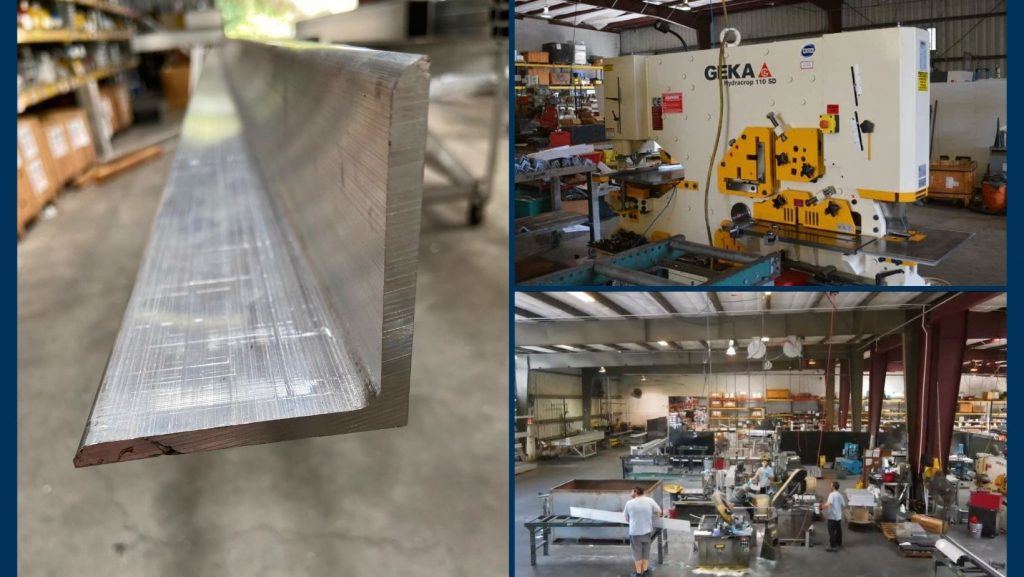

Installing a boat lift into an existing boat house can be tricky. That is why Diversion Boat Lift Company is one of our preferred partners. They have the experience and technical knowledge to make sure that even the most difficult installations are done safely and will stand the test of time.

Installing a boat lift into an existing boat house can be tricky. That is why Diversion Boat Lift Company is one of our preferred partners. They have the experience and technical knowledge to make sure that even the most difficult installations are done safely and will stand the test of time. “At Diversion Boat Lift Company, we approach every lift opportunity with an engineering mindset. Together with IMM, we designed this custom lift to meet the specifications of the boat and the boathouse characteristics. Almost every job has its unique set of challenges; together with IMM we have been tackling them, while making our customers happy,” said Steve Fantauzzo, principle at Diversion Boat Lift Company.

“At Diversion Boat Lift Company, we approach every lift opportunity with an engineering mindset. Together with IMM, we designed this custom lift to meet the specifications of the boat and the boathouse characteristics. Almost every job has its unique set of challenges; together with IMM we have been tackling them, while making our customers happy,” said Steve Fantauzzo, principle at Diversion Boat Lift Company.

Powerhead Drive Systems

Powerhead Drive Systems

These shared values have allowed a partnership between IMM Quality Boat Lifts and Williamson Bros Marine Construction to flourish. The recent installation of a custom boat lift for a specialized Sherp vehicle highlights how our two companies work together to create solutions for any custom marine construction project.

These shared values have allowed a partnership between IMM Quality Boat Lifts and Williamson Bros Marine Construction to flourish. The recent installation of a custom boat lift for a specialized Sherp vehicle highlights how our two companies work together to create solutions for any custom marine construction project.

We believe the Superlift is the finest industrial-duty boat lift in service. Our accomplished engineering team has developed next-level design innovations that transform and improve the functionality of our Superlift drive. It has revolutionized the boat lift industry.

We believe the Superlift is the finest industrial-duty boat lift in service. Our accomplished engineering team has developed next-level design innovations that transform and improve the functionality of our Superlift drive. It has revolutionized the boat lift industry.