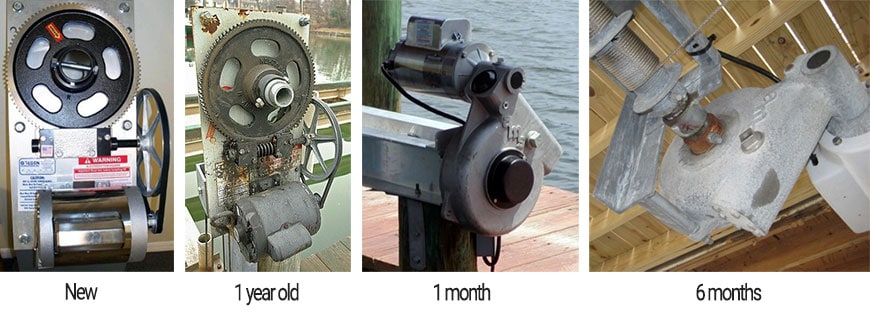

There can be little doubt that Mother Nature will ruin machinery if it is not protected properly. A marine environment is particularly harsh and most people realize how damaging corrosion and electrolysis can be to boats. However, few realize just how vulnerable boat lift drive systems are to environmental degradation. The drive system components that are most vulnerable are the motors, gearboxes and the moving parts (e.g. sprockets, chains, belts, etc.). Let’s take a look at what can happen to unprotected drive systems, especially the motors.

General Benefits of a Cover

The IMM Quality Boat Lifts covers have been specially designed to protect and preserve the drive components. The covers are made from high-density polyethylene to provide chemical, U.V. and corrosion resistance. The U.V. protection will minimize fading, sun damage and reflect heat from the sun to lower the surface temperature of the drive components, thus protecting the motors from overheating. We use a roto-molding process to make the covers extra thick to provide the highest level of impact resistance and durability. They will protect your drive components from rocks, lures, limbs, aerial assaults from birds, sea salt, and the elements while keeping everything looking new.

Harsh marine environment quickly ruins uncovered drive components

The covers also protect the drive components from grime and grit. The housing of the gear boxes are made from cast aluminum so exposure to the elements simply affects the cosmetic appearance. However, the drive shaft from the gearbox is made from carbon steel so that it can withstand the torque. This drive shaft along with its seals is vulnerable to breaking down in a marine environment and protecting them with a cover greatly extends the life of the gearbox. In addition, the sprockets and many other drive components require lubrication to allow them to turn easily and to protect them from corrosion.

Open drive systems allow the weather to wash away the lubrication, necessitating more frequent maintenance with re-application of lubricant, otherwise, the moving parts will make loud noises and will eventually bind. Open drive systems also allow grit to accumulate on the components which will wear down the sprockets, sheaves and other moving parts much more quickly than when they are protected by a cover. With all this grime and grit it is a good thing that the IMM Quality covers were designed to be simple to clean using just a mild detergent and water.

Motors

There are many kinds of motors, but the types most commonly used by boat lift manufacturers are open drip proof (ODP), totally enclosed (either non-ventilated (TENV) or fan cooled (TEFC)), stainless steel and extreme duty washdown motors.

Using a cover essentially eliminates condensation inside a motor. The cover greatly slows the cooling of the metal, the cover limits the volume of air around the motor and the cover limits the turnover of moist air around the motor by lowering air flow. To help you understand why covers eliminate condensation, think about your car and how water can condense on it as dew or frost. Then think about how cars parked inside garages are protected from this condensation. Even though the garage is not air tight, is not insulated or heated, cars parked in garages do not get frost (in winter) or dew (in summer) on their windshields on the same night cars parked outside do have condensation. The same scientific principles protect your boat lift drive components from condensation when they are covered.

Conclusion

There are many reasons why owning a boat lift that has a cover for the drive components is a wise idea. Covering the drive components will protect them from the elements and greatly extend their service life. A cover will also preserve the beauty of your motor and gearbox in addition to increasing the resale value of your lift. A good cover improves the overall aesthetics of the lift giving a sleek, clean look compared to the clunky, industrial look of exposed machinery. Given all the benefits of a covered drive, why would anyone choose to do otherwise?