When it comes to watercraft ownership, boat lifts are an essential investment for individuals who own small boats, kayaks, or personal watercrafts. These ingenious systems not only provide convenience but also offer numerous benefits such as protection against water damage, increased longevity of vessels, and hassle-free maintenance. In this article, we will explore the world of boat lifts, their types, advantages, and considerations for choosing the right one for your small watercraft.

1. The Importance of Boat Lifts

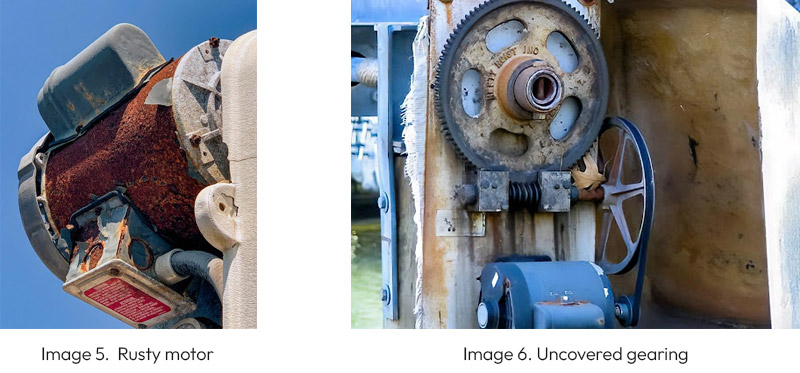

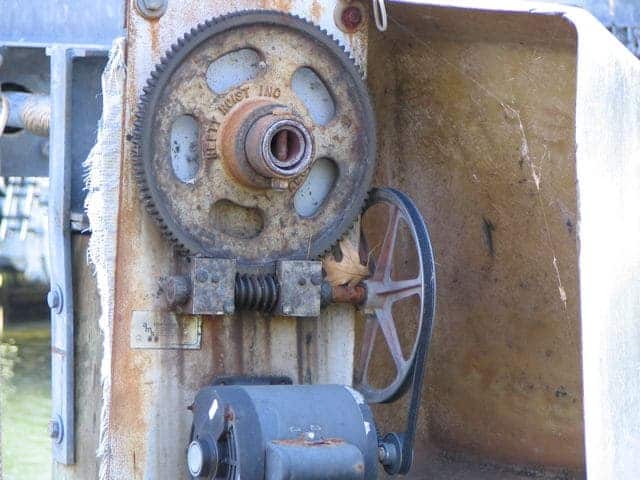

Owning a small boat, kayak, or personal watercraft often means dealing with the challenges of storage and maintenance. Boat lifts offer an effective solution by raising your watercraft out of the water when not in use. This elevation eliminates concerns related to exposure to marine growth, hull damage caused by floating debris, and the corrosive effects of saltwater. By keeping your vessel out of the water, you can significantly extend its lifespan and reduce maintenance costs.

2. Types of Boat Lifts

Boat lifts come in various types, each designed to cater to specific watercraft and docking situations. The most common types for small boats, kayaks, and personal watercraft include:

a) Vertical Boat Lifts: Ideal for small boats and watercraft, these lifts elevate the vessel straight up out of the water, saving space and allowing easy access for boarding.

b) Floating Dock Lifts: Designed for kayaks and personal watercraft, these lifts feature a floating platform that supports and raises the watercraft out of the water. They are versatile and can adapt to changing water levels.

c) PWC Lifts: Specifically designed for personal watercraft, these lifts often come with adjustable bunks or cradles to secure the watercraft. They are compact, easy to use, and protect your valuable personal watercraft from the elements.

d) Dual PWC Jet Ski Lifts: For those who own multiple personal watercraft, a dual PWC jet ski lift is an excellent solution. These lifts are specifically designed to accommodate two jet skis simultaneously, providing efficient storage and easy access to both watercraft. Dual PWC lifts come in various configurations, including side-by-side lifts or lifts with a shared platform.

e) Kayak Lifts: These lifts are designed to provide a simple solution for getting kayaks in and out of the water quickly. We have three generations of engineering experience, which has been utilized to create kayak dock lifts that are user-friendly, space-efficient, and durable enough to last a lifetime.

f) Ascension Stair Lift: This revolutionary lift offers convenient water access with an adjustable height boarding platform attached to a set of stairs with self-leveling steps. The boarding platform is capable of going both above and below your deck height.

3. Advantages of Boat Lifts for Smaller Watercrafts

Investing in a boat lift offers a multitude of advantages for small boat, kayak, and personal watercraft owners:

- Protection from the Elements: Boat lifts keep your watercraft safely elevated, protecting them from damage caused by wind, waves, and harsh weather conditions.

- Easy Access and Docking: With a boat lift, launching and docking your watercraft becomes a breeze. You can quickly and conveniently access your vessel without the need for ramps or trailers.

- Reduced Maintenance: By keeping your boat or watercraft out of the water, you can minimize maintenance requirements such as cleaning, painting, and bottom maintenance, saving both time and money.

- Increased Security: Boat lifts deter theft and unauthorized use, as your watercraft is securely elevated out of reach when not in use.

4. Choosing the Right Boat Lift

Selecting the appropriate boat lift for your small boat, kayak, or personal watercraft is crucial. Consider the following factors before making a purchase:

- Weight Capacity: Ensure the lift can safely support the weight of your watercraft. You can use our handy Boat Lift Capacity Calculator to help determine the best boat lift for your watercraft.

- Size and Dimensions: Choose a lift that accommodates the length, width, and height of your vessel.

- Water Conditions: Take into account the water depth, current, and fluctuation when selecting a boat lift to ensure stability and functionality.

- Ease of Use: Look for lifts with user-friendly features such as remote controls, automatic leveling, and adjustable settings for convenience.

As you can clearly see, the patented IMM Quality Boat Lifts wedge lock makes adjusting cable length to level the cradles much easier.

As you can clearly see, the patented IMM Quality Boat Lifts wedge lock makes adjusting cable length to level the cradles much easier.